Page 38 - Realm Catalog

P. 38

36 www.roofix.in

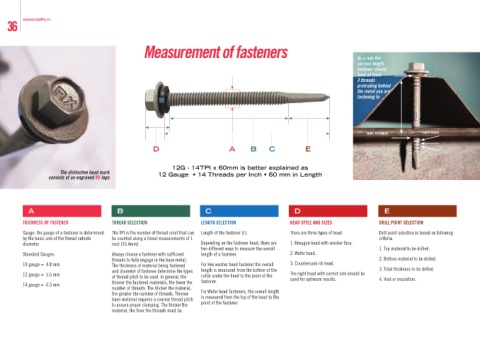

Measurement of fasteners

As a rule the

correct length

fastener should

have at least

3 threads

protruding behind

the metal you are

fastening to

TOTAL THICKNESS THREE HEADS

D A B C E

12G - 14TPI x 60mm is better explained as

The distinctive head mark 12 Gauge • 14 Threads per Inch • 60 mm in Length

consists of an engraved RX logo

A B C D E

THICKNESS OF FASTENER THREAD SELECTION LENGTH SELECTION HEAD STYLE AND SIZES DRILL POINT SELECTION

Gauge: the gauge of a fastener is determined The TPI is the number of thread crest that can Length of the fastener (L). There are three types of head. Drill point selection is based on following

by the basic size of the thread outside be counted along a lineal measurements of 1 criteria.

diameter. inch (25.4mm). Depending on the fastener head, there are 1. Hexagon head with washer face.

two different ways to measure the overall 1. Top material to be drilled.

Standard Gauges: Always choose a fastener with sufficient length of a fastener. 2. Wafer head.

threads to fully engage in the base metal. 2. Bottom material to be drilled.

10 gauge = 4.8 mm The thickness of material being fastened For Hex washer head fastener the overall 3. Countersunk rib head.

and diameter of fastener determine the types length is measured from the bottom of the 3. Total thickness to be drilled.

12 gauge = 5.5 mm of thread pitch to be used. In general, the collar under the head to the point of the The right head with correct size should be

thinner the fastened materials, the fewer the fastener. used for optimum results. 4. Void or insulation.

14 gauge = 6.3 mm

number of threads. The thicker the material,

the greater the number of threads. Thinner For Wafer head fasteners, the overall length

base material requires a coarser thread pitch is measured from the top of the head to the

to assure proper clamping. The thicker the point of the fastener.

material, the finer the threads must be.