Page 45 - Realm Catalog

P. 45

43

Technical Specifications

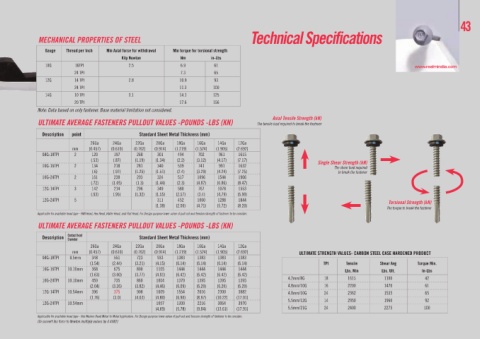

MECHANICAL PROPERTIES OF STEEL

Gauge Thread per Inch Min Axial force for withdrawal Min torque for torsional strength

Kilp Newton Nm in-Lbs

10G 16TPI 2.5 6.9 61 www.realmindia.com

24 TPI 7.3 65

12G 14 TPI 2.8 10.9 93

24 TPI 11.3 100

14G 10 TPI 3.1 14.1 125

20 TPI 17.6 156

Note: Data based on only fastener. Base material limitation not considered.

Axial Tensile Strength (kN)

ULTIMATE AVERAGE FASTENERS PULLOUT VALUES -POUNDS -LBS (KN) The tensile load required to break the fastener

Description point Standard Sheet Metal Thickness (mm)

26Ga 24Ga 22Ga 20Ga 18Ga 16Ga 14Ga 12Ga

mm (0.457) (0.610) (0.762) (0.914) (1.219) (1.524) (1.905) (2.692)

08G-18TPI 2 120 197 268 301 494 702 961 1615

(.53) (.87) (1.19) (1.34) (2.2) (3.12) (4.17) (7.17) Single Shear Strength (kN)

10G-16TPI 2 134 218 281 340 539 741 991 1632 The shear load required

(.6) (.97) (1.25) (1.51) (2.4) (3.29) (4.24) (7.25) to break the fastener

10G-24TPI 2 161 238 293 324 517 1096 1544 1906

(.72) (1.05) (1.3) (1.44) (2.3) (4.87) (6.86) (8.47)

12G-14TPI 3 142 214 296 349 580 767 1078 1553

(.63) (.95) (1.32) (1.55) (2.57) (3.4) (4.79) (6.90)

12G-24TPI 5 311 452 1060 1288 1844 Torsional Strength (kN)

(1.38) (2.00) (4.71) (5.72) (8.20)

The torque to break the fastener

Applicable for available head type - PAN Head, Hex Head, Wafer Head, and Flat Head. For Design purpose lower value of pull out and tension strength of fastener to be consider.

ULTIMATE AVERAGE FASTENERS PULLOUT VALUES -POUNDS -LBS (KN)

Description Contact head Standard Sheet Metal Thickness (mm)

Diameter

26Ga 24Ga 22Ga 20Ga 18Ga 16Ga 14Ga 12Ga

mm (0.457) (0.610) (0.762) (0.914) (1.219) (1.524) (1.905) (2.692) ULTIMATE STRENGTH VALUES- CARBON STEEL CASE HARDENED PRODUCT

08G-18TPI 8.5mm 348 551 723 933 1383 1383 1383 1383

(1.54) (2.44) (3.21) (4.15) (6.14) (6.14) (6.14) (6.14) TPI Tensile Shear Avg Torque Min.

10G-16TPI 10.10mm 368 675 890 1105 1444 1444 1444 1444 Lbs. Min Lbs. Ult. In-Lbs

(1.63) (3.00) (3.77) (4.91) (6.42) (6.42) (6.42) (6.42)

10G-24TPI 10.10mm 459 735 860 1004 1370 1395 1395 1395 4.2mm/8G 18 1615 1100 42

(2.04) (3.26) (3.82) (4.46) (6.09) (6.20) (6.20) (6.20) 4.8mm/10G 16 2200 1470 61

12G-14TPI 10.54mm 396 375 908 1009 1554 2016 2300 3882 4.8mm/10G 24 2362 1535 65

(1.76) (3.0) (4.03) (4.88) (6.90) (8.97) (10.22) (17.01)

12G-24TPI 10.54mm 1057 1300 2216 3064 3970 5.5mm/12G 14 2950 1960 92

(4.69) (5.78) (9.84) (13.61) (17.91) 5.5mm/21G 24 2400 2275 100

Applicable for available head type - Hex Washer Head Metal to Metal Application. For Design purpose lower value of pull out and tension strength of fastener to be consider.

(To convert lbs force to Newton multiply values by 4.4482)